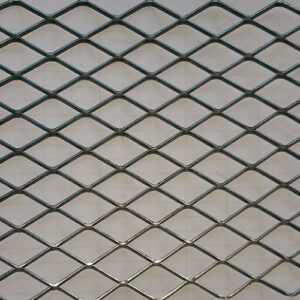

When it comes to selecting the ideal expanded metal mesh for your needs, understanding the various factors involved can ensure you make the right choice. Expanded metal mesh is a versatile material used in numerous applications, from industrial to decorative purposes. Here’s a detailed guide to help you navigate the selection process:

1. Understand Your Application Requirements

Identify the Purpose:

-

Security: For security purposes such as fencing and barriers, choose a mesh with smaller openings and thicker strands for strength.

-

Filtration: If using the mesh for filtration, select a mesh with the appropriate aperture size to filter out the desired particles.

-

Decorative: For aesthetic applications like facades or interior design, focus on mesh patterns, finish, and visual appeal.

Load and Stress:

-

Consider the load-bearing requirements. Heavier loads necessitate a mesh with thicker strands and smaller apertures.

2. Material Selection

Steel Type:

-

Carbon Steel: Offers strength and durability, suitable for most applications.

-

Stainless Steel: Provides excellent corrosion resistance, ideal for outdoor or harsh environments.

-

Aluminum: Lightweight and corrosion-resistant, perfect for less demanding applications where weight is a factor.

Coatings and Finishes:

-

Galvanized: Provides additional corrosion resistance for steel mesh.

-

PVC Coating: Offers both corrosion resistance and aesthetic options with various colors.

3. Mesh Specification

Strand Thickness and Width:

-

Thicker and wider strands increase strength but reduce flexibility.

-

Select the appropriate thickness based on the structural requirements of your application.

Aperture Size and Shape:

-

Aperture size determines the mesh’s ability to block or allow passage.

-

Common shapes include diamond, square, and hexagonal. Choose based on both functional and aesthetic needs.

Sheet Size and Thickness:

-

Ensure the mesh sheet size fits your installation area without excessive cutting or waste.

-

The overall thickness of the sheet contributes to its strength and durability.

4. Quality and Compliance

Industry Standards:

-

Ensure the mesh meets relevant industry standards for quality and safety. Look for certifications like ISO or ASTM standards.

Manufacturer Reputation:

-

Choose a reputable manufacturer known for consistent quality and reliable products. Check reviews and seek recommendations.

5. Installation Considerations

Ease of Installation:

-

Consider the ease of handling and installing the mesh. Some meshes are easier to cut and shape than others.

Compatibility with Existing Structures:

-

Ensure the selected mesh can be easily integrated with your existing structures or frameworks.

Conclusion

Selecting the right expanded metal mesh involves a careful consideration of your specific application needs, material properties, mesh specifications, quality standards, and installation requirements. By following this guide, you can make an informed decision that ensures durability, functionality, and aesthetic appeal.

For any further assistance or to explore our range of expanded metal mesh products, feel free to contact our expert team. We are here to help you find the perfect solution for your needs.

We hope this guide helps you in choosing the right expanded metal mesh. If you have any questions or need personalized recommendations, please reach out to us!