July 28, 2024—The versatile applications of metal crimped mesh have gained widespread recognition, highlighting its essential role across various industries.

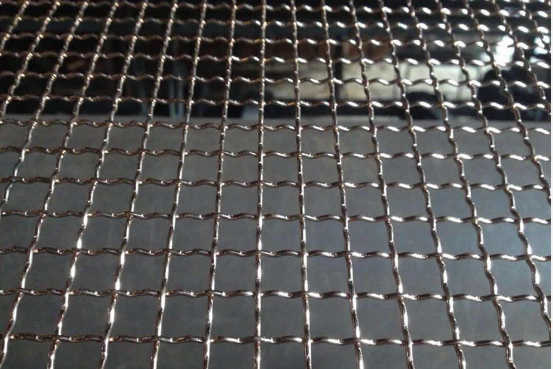

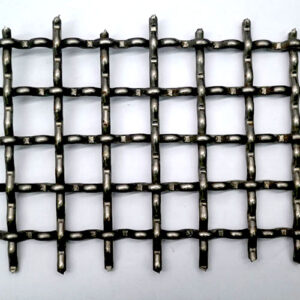

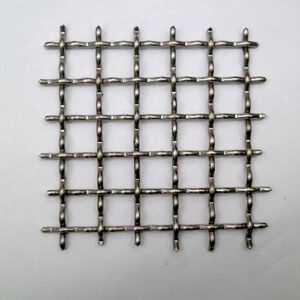

Metal crimped mesh, known for its durability and strength, is utilized in a wide array of applications. Its unique structure, created by weaving metal wires into a grid pattern and crimping them at intersections, provides exceptional stability and resilience, making it suitable for both industrial and commercial uses.

Key Applications

-

Filtration: Metal crimped mesh is widely used in filtration systems due to its ability to effectively separate solids from liquids or gases. It is a crucial component in water treatment plants, chemical processing units, and oil refineries.

-

Construction: In the construction industry, crimped mesh is utilized for reinforcing concrete, providing stability and support in various structural elements. It is also used for fencing and partitioning in construction sites.

-

Mining and Quarrying: The mining and quarrying industries use metal crimped mesh for screening and grading materials. Its durability and strength allow it to withstand the harsh conditions of these environments, ensuring efficient separation of ores and aggregates.

-

Agriculture: Farmers and agricultural businesses employ crimped mesh for creating protective enclosures for livestock and crops. Its robustness ensures long-lasting protection against pests and predators.

-

Food Processing: In food processing, crimped mesh is used for sieving and sorting products. Its non-toxic and corrosion-resistant properties make it ideal for handling food items.

-

Decorative Uses: Metal crimped mesh is also used in architectural and decorative applications. Its aesthetic appeal and structural integrity make it a popular choice for designing facades, interiors, and artistic installations.

Industry Expert Insights

Industry experts have emphasized the importance of metal crimped mesh in enhancing efficiency and safety across these diverse applications. Dr. Emily Turner, a materials engineer, stated, “The versatility and strength of metal crimped mesh make it indispensable in many sectors. Its ability to withstand extreme conditions while maintaining structural integrity is a significant advantage.”

Market Trends

The demand for metal crimped mesh is expected to grow steadily as industries continue to recognize its benefits. Leading manufacturers are investing in advanced production techniques to improve the quality and performance of crimped mesh, catering to the evolving needs of various sectors.

Consumers and businesses are showing increased interest in this material, driven by its wide range of applications and long-term cost-effectiveness. The market is poised for growth, with new innovations and applications continually emerging.

Overall, metal crimped mesh has established itself as a vital material across multiple industries. Its durability, versatility, and strength ensure that it will continue to play a crucial role in enhancing operational efficiency and safety in various applications.